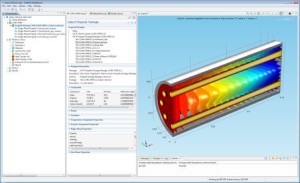

COMSOL are leaders in the simulation of chemically reacting systems. Specifically, the Chemical Reaction Engineering module readily couples transport phenomena—computational fluid dynamics (CFD), and mass and energy transport—to chemical reaction kinetics to model space-dependent reacting systems and chemical reactors in 1D, 2D, 2D axisymmetry and 3D. COMSOL version 4 features a CAPE-OPEN thermodynamic and physical properties interface, enabling COMSOL products to access property calculations from CAPE-OPEN compliant physical property packages. This provides increased accuracy in models based around the physics of flow, heat and mass transfer, where they can also include chemical reaction kinetics. The CAPE-OPEN thermodynamic and physical properties interface supports both CAPE-OPEN Thermo 1.1 and CAPE-OPEN Thermo 1.0 standards. External property packages are accessed through a graphical user interface, allowing for compound constant import, single-phase, two-phase, pressure-dependent, and temperature-dependent property calculations. From the interface, you select the appropriate property package, and set up functions for evaluation of the desired property calculations. The functions can then be used directly in the Chemical Reaction Engineering Module. Here they are then explicitly incorporated into the equations for the solution of momentum, mass and energy balances to provide space-dependent models of reacting systems. The reactor model presented here exemplifies the use of the interface. It treats a three-dimensional steam reforming reactor where fluid flow, temperature, and composition are simulated for time and space dependency.